All terrain

-

The championship cars are a one design fleet, a fully electric SUV, named ODYSSEY 21. In order to withstand the harsh conditions it will face, the car’s peak 400kw (550bhp) output is capable of firing the 1895-kilogram, 2.3-metre wide e-SUV from 0-62mph in 4.5 seconds, at gradients of up to 130 per cent.

-

Spark racing

Each vehicle comprises a common package of standardised parts, manufactured by Spark Racing Technology with a battery produced by Williams Advanced Engineering. This encompasses a niobium-reinforced steel alloy tubular frame, as well as crash structure and roll cage, whilst its tyres, the vehicle’s crucial connection to these terrains are designed especially for the extreme conditions by founding partner Continental Tyres.

For Season 1, teams had the choice to use Extreme E’s bodywork, or work with an automotive partner, such as Chip Ganassi has done with the GM HUMMER EV, to put its own bodywork on the common chassis in order to utilise its platform to speak directly to the consumer market.

-

Batteries

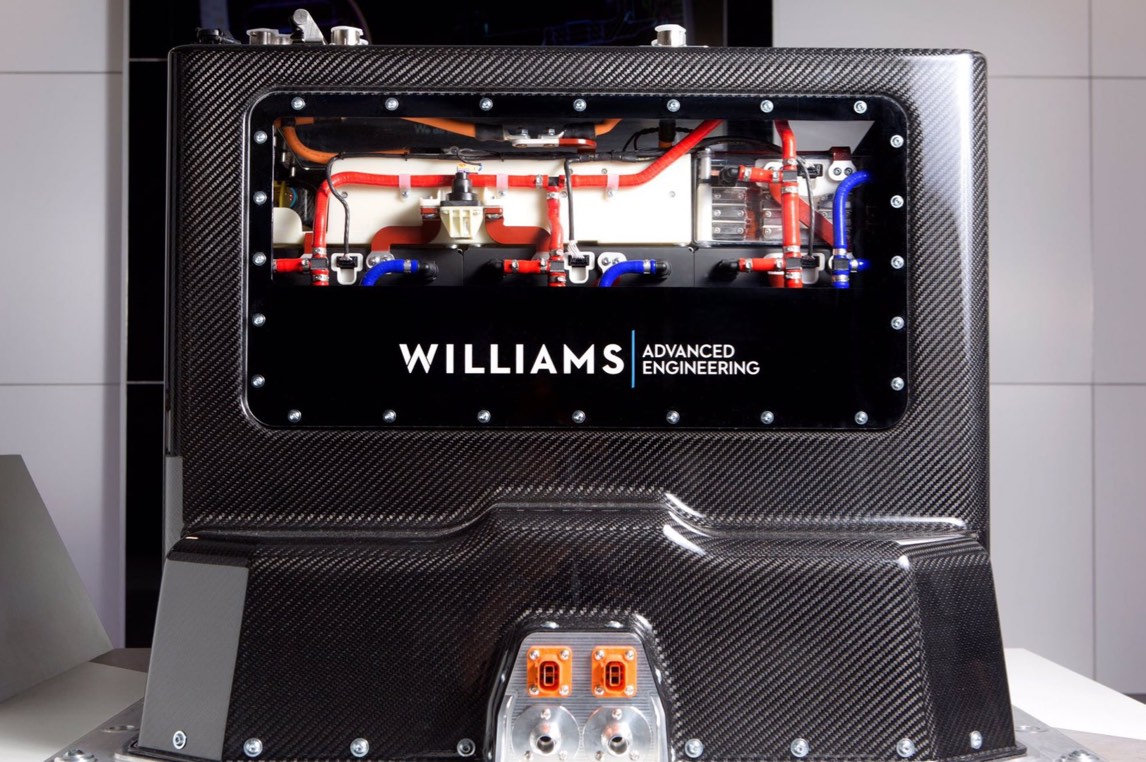

The batteries are specially-designed and developed by Williams Advanced Engineering, plugging into the expertise and experience of the same minds who supply the batteries for Gen3 of the ABB FIA Formula E World Championship, starting in 2023.

Designed to withstand the extreme temperatures, conditions and terrains, the batteries will produce a maximum power output of 400kW (equivalent to approx. 550bh). Teams have been provided with identical 54kWh battery packs to be used in the first two seasons of Extreme E.

-

Tyres

The tyres have been designed and produced by Extreme E’s Founding Partner, Continental.

The German tyre brand carefully examined the requirements of the race series and built an ultra-high-performance tyre that specifically addresses the needs of the competing teams. This performance-optimised tyre is not just built for extreme conditions, but also for the unique characteristics of Extreme E’s pure electric SUVs.There will be one specification of tyre based on the Continental CrossContact series, a tyre with a specially-designed tread to enhance traction and stability on practically any surface. The tyres for the ODYSSEY 21 will be able to cope with all conditions, from the scorching heat to blistering cold plus muddy, sandy or icy terrains.

Each tyre will be fitted with Continental’s state-of-the-art ContiConnect, a digital tyre-monitoring system meaning greater safety for car and driver. The system collects, measures and analyses data such as tyre pressure and temperature in real time, transmitting that information to the driver via a display in the cockpit. Each team is allocated one set of tyres per race, and two used tyres from the previous race.

-

Chassis

CBMM | Niobium is a founding supplier of Extreme E and the championship’s official Niobium Technology Supplier and Chassis Technology Supplier.

Critical to the automotive sector, niobium produces stronger, lighter and more sustainable cars with better energy efficiency. Its technologies are already widely applied in different areas, including light-weighting, safety, emissions reduction and electronics that will help lead to a sustainable sector transformation. Key applications of niobium in the Mobility sector include chassis, brakes and exhaust systems, drivetrains, batteries and EV charging stations and any number of ancillary components. Its qualities mean materials can be made lighter, stronger, more robust and more reliable – all while being more sustainable than other materials.

Each of these qualities will be key to ensuring Extreme E’s SUVs can cope with, and thrive within, the competition’s five formidable environments. Increased lightness breeds energy savings and improved performance, and the added strength and durability afforded by niobium technology will assist the Extreme E chassis in dealing with the toughest challenges thrown their way.

CBMM | Niobium already enjoys a long-standing relationship with the ABB FIA Formula E Championship, focused on building awareness of niobium technology and promoting partnerships to explore and progress the growing potential of sustainable mobility.

-

Exterior

The exterior shell of the ODYSSEY 21 is made from Bcomp’s natural flax fibre, in a bid to be more sustainable. The two products of the shell, ampliTex™ and powerRibs™, are made from natural flax fibres and carry a variety of environmental benefits including a 75 per cent reduction in carbon footprint from cradle to gate, all whilst providing the best in safety standards.

specificatons

-

FEATURE SPEC. SHIP AREA/SPEC. Overall Length 4.401m Overall width 2.3m Overall height 1.864m Front track 2m Rear track 2m Ride Height 450mm Wheelbase 3.001m Weight 1895kg Battery Capacity 40kWh of usable energy

Twin 250KW motors (550bhp equivalent)Acceleration 0-100km/h (0-62mph) 4.5 seconds Gradient capability 40° (80% slope) to 53° (130% slope est. depending on surface Suspension travel 385mm SPECIFICATION PARTS Tubular frame constructed of Niobium reinforced steel alloy Suspension & dampers Double wishbone with three-way adjustable mono-damper.

Hydraulic bump and rebound stopBraking Six-piston Alcon caliper

Iron disk & padsSteering Electrical power steering system Battery Williams Advance Engineering bespoke liquid cooled 3600 cell unit Tyres Continental CrossContact race tyre made using ContiRe.Tex recycling technology